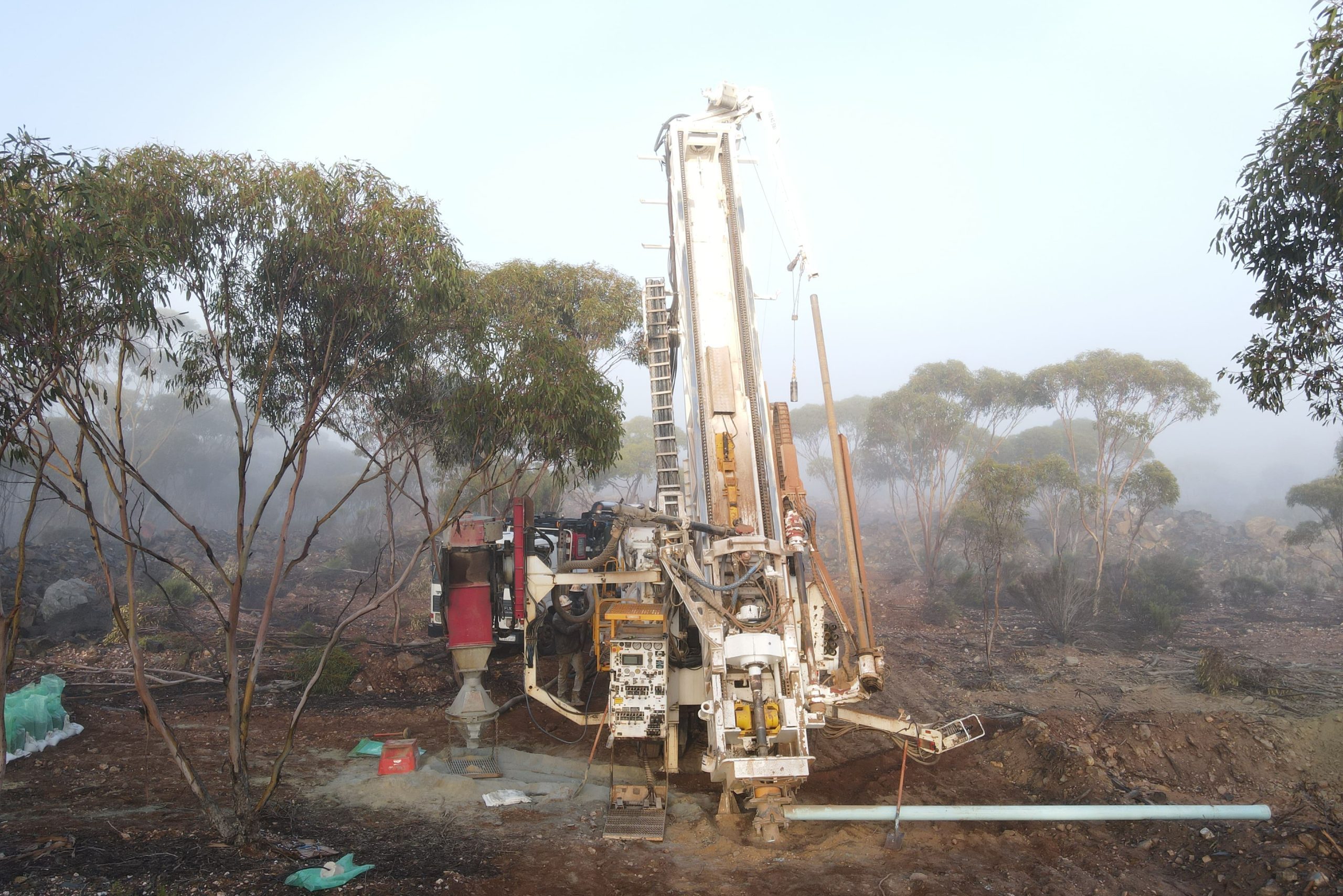

Impact Drilling’s fleet consists of a range of machines suitable for your Air Core (AC) and Reverse Circulation (RC) projects.

AC drilling uses a three-bladed steel or tungsten drill bit with a hollow drill rod, while RC drilling uses a piston-driven “hammer” to drive a tungsten-steel bit into the rock.

Both involve the use of compressed air to flush out samples. However, AC drilling is ideal where unconsolidated ground is present. RC drilling on the other hand, uses the added element of concussive force to power the drill bit, pulverising the rock in its path. This makes RC drilling ideal for harder ground.